Surface Generation was established 20 years ago to develop and commercialise the unique Production to Functional Specification (PtFS) process. Today clients use a multitude of flavours of this ground-breaking tech to optimise their parts / processes / materials (e.g. self-reinforced hydroxyapatite) to make next-gen products such as dead optics, monolithic thrust reverser cascades, thermoplastic structural guide vanes (SGV’s) and AR / VR / XR headset components – all impossible with traditional manufacturing techniques.

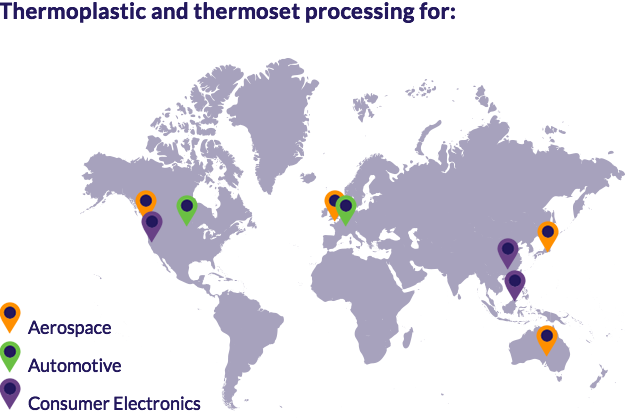

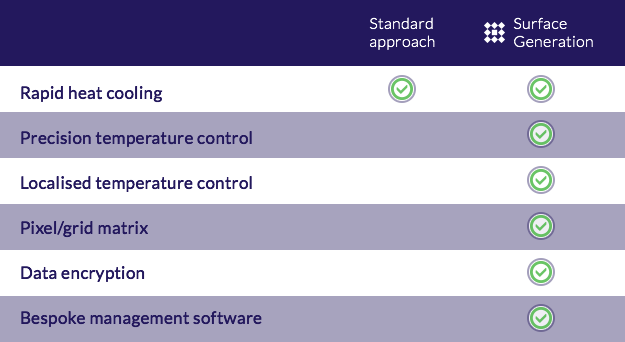

PtFS enables step changes in cost, quality and delivery that provide smart, intelligent and energy efficient solutions to the world’s leading manufacturing OEMs and material suppliers. Principle markets include:

- Aerospace

- Automotive

- Consumer Goods

- Medical

- Energy

Dedicated hardware, automation, composites, moulding and optics teams provide:

- Equipment

- Consulting

- Solution

- Processes